Project Information:

Author: Ivana Moreno (me), Emilia Kaitazoff, Sara Palmiotti, Eleonora Zorzi

Teacher: Ubi de Feo (Arduino)

Course: CAS1 - Designing Tangible Interfaces

SUPSI, MaInD, 2019/20

Tools used:

Vector diagrams: Adobe Illustrator

Image editing: Adobe Photoshop

Prototype: 3D modeling - Autodesk

Fusion 360, Laser Cutter, 3D Printer,

Coding - Arduino Uno

Fusion 360, Laser Cutter, 3D Printer,

Coding - Arduino Uno

Video editing: Adobe Premiere

Abstract

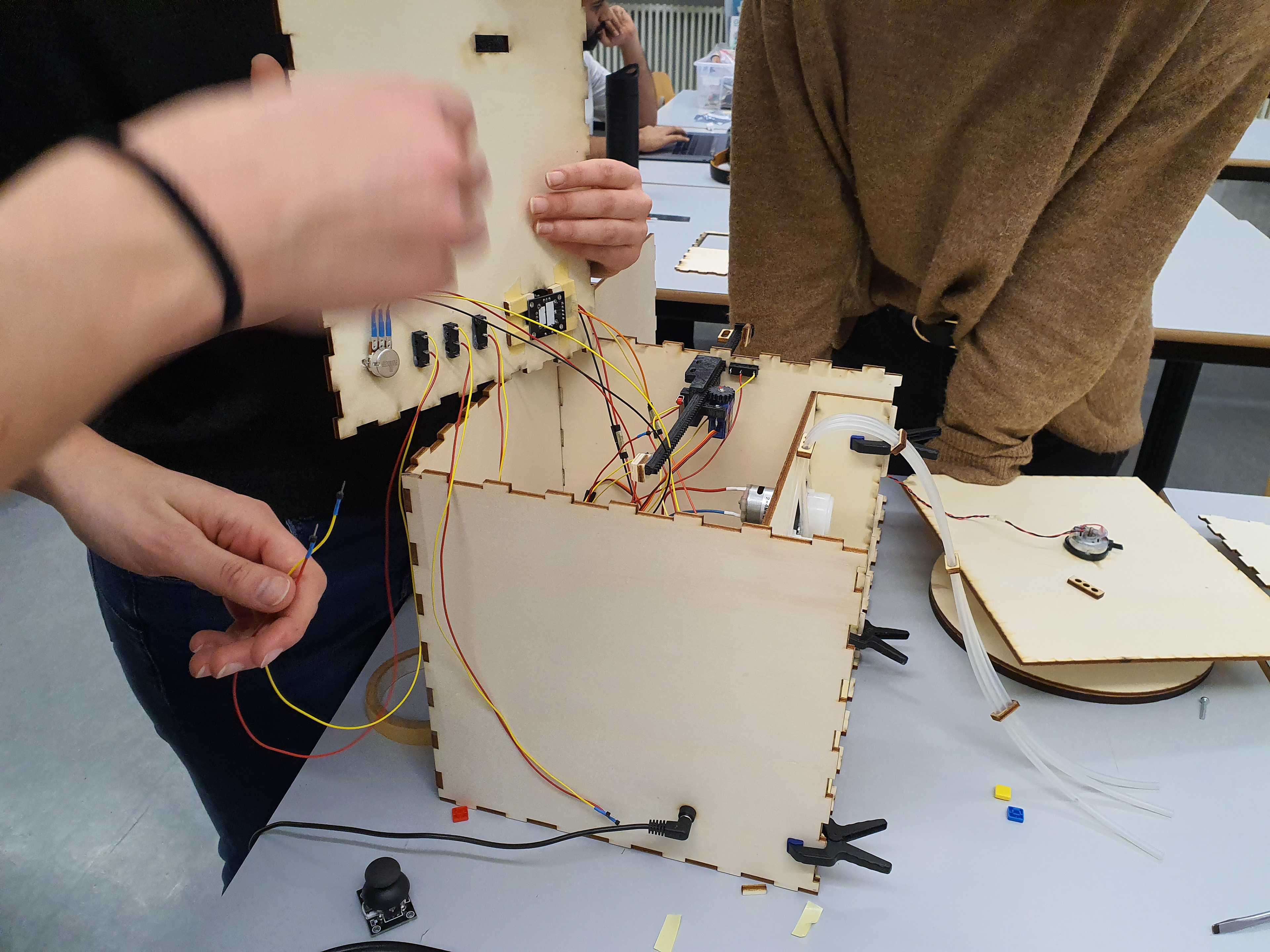

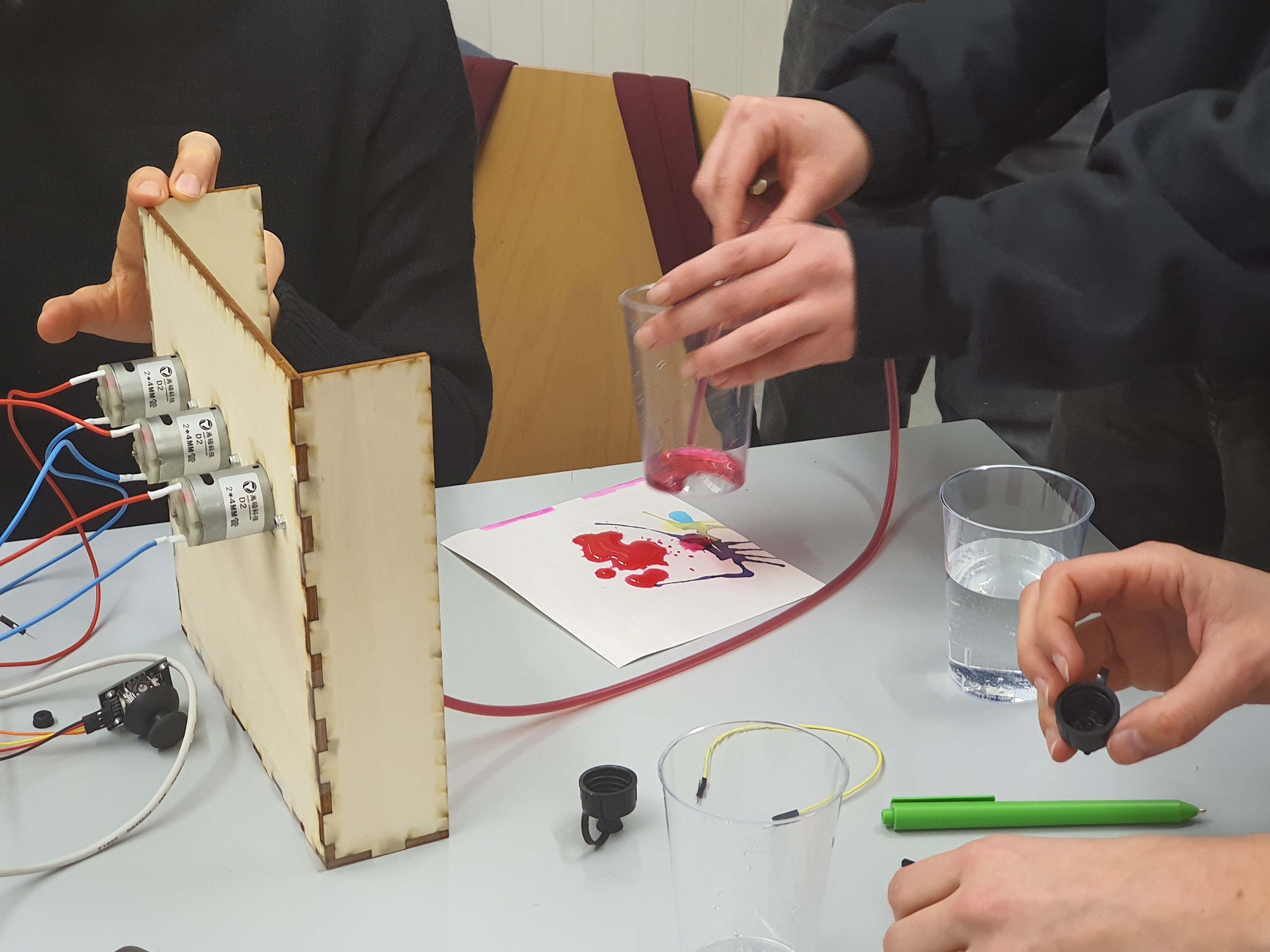

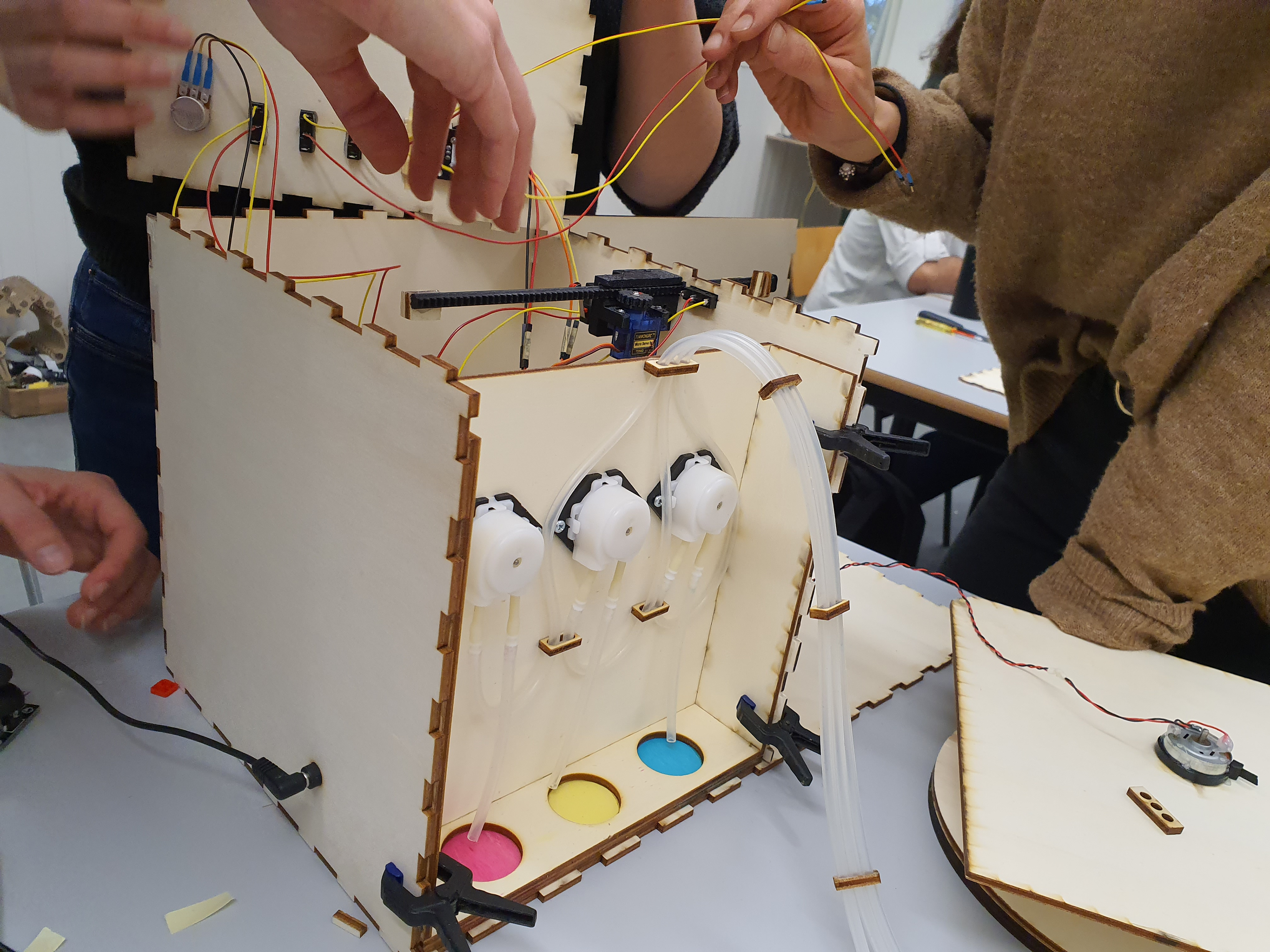

YMCK is a mixer of a plotter machine and an inkjet printer. Our goal was to build a machine capable of creating an abstract piece of art. For that we combined the features of Arduino with digital fabrication to achieve the right visual outcome. YMCK comes from the original initials “CMYK” of cyan, magenta, yellow and black, the colors used by printers. The combination of these primary colors are the base to obtain a wider palette.

Interface and interaction modality & User experience

It consists of a colorful spinning plate machine which the user can manage to create a less predictable painting. The user interaction occurs by controlling the speed of the spinning plate, choosing the color and also where it will be placed. The spin is what gives the randomness touch to the outcome. The user experience happens with the surprising result. The painting can be then signed by the user.

List of components

Hardware and electronic components' structure:

- 1 Arduino UNO;

- Analog JoyStick;

- 5 Limit switches;

- 5 resistors 10KΩ;

- 1 potentiometer;

- 1 servo motor Micro Servo 9g SG90;

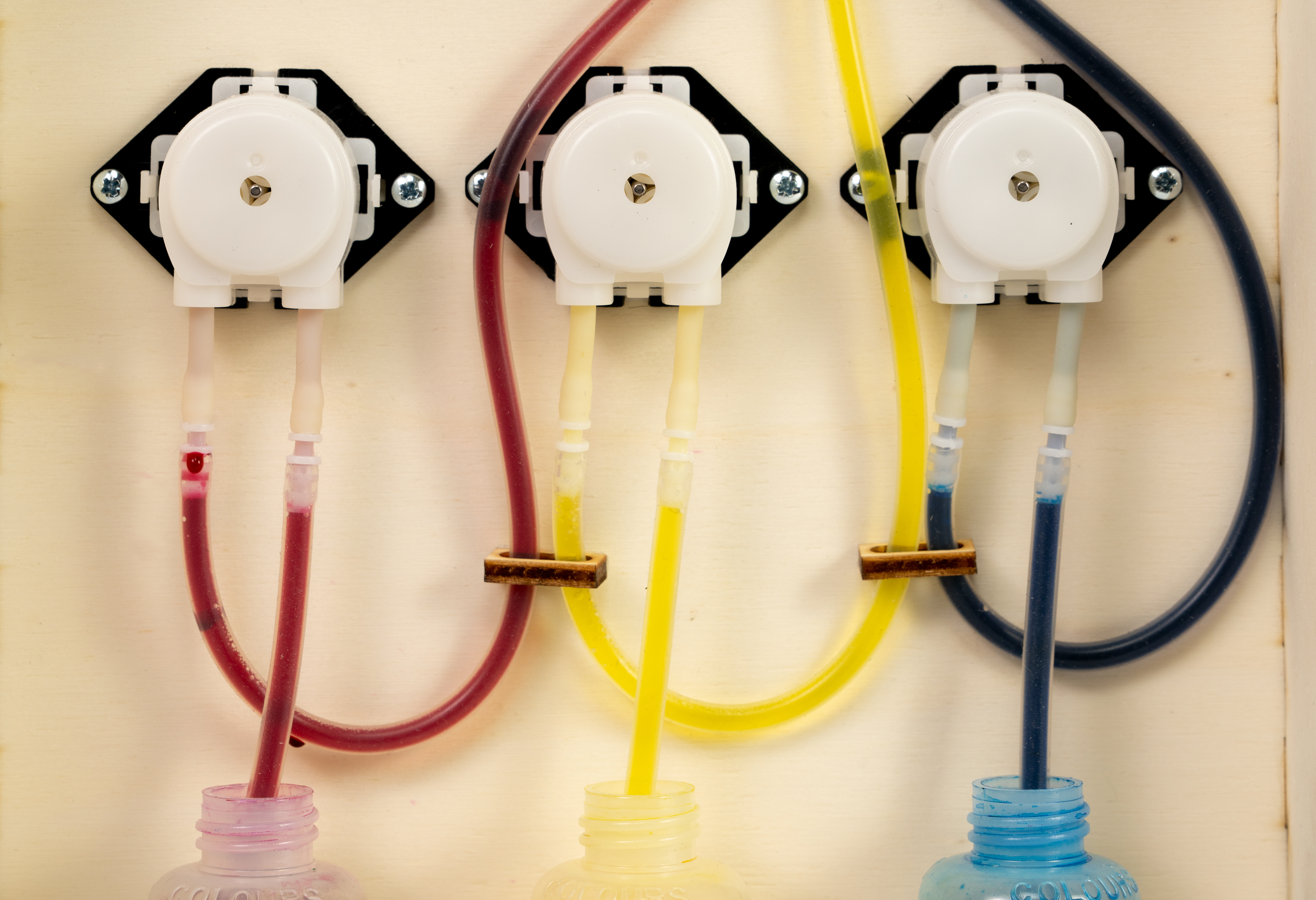

- 3 peristaltic pumps;

- 1 12v DC motor;

- 1 Adafruit Motor shield v2;

- 2 9V batteries;

- 1 MOSFET IRF540N.

Research and development context

The drawings created recall the works of abstract expressionism and because of it, YMCK could be proposed as an attraction for modern art exhibitions. The project could also be set in the educational context, a way to help kids express themselves during art lectures, experimenting with colours and paintings .

For further development, it has gotten clear from the first prototype that the internal walls where the spinning plate lay down needed to be waterproof, so the ink wouldn't be absorb by the wood.

For further development, it has gotten clear from the first prototype that the internal walls where the spinning plate lay down needed to be waterproof, so the ink wouldn't be absorb by the wood.